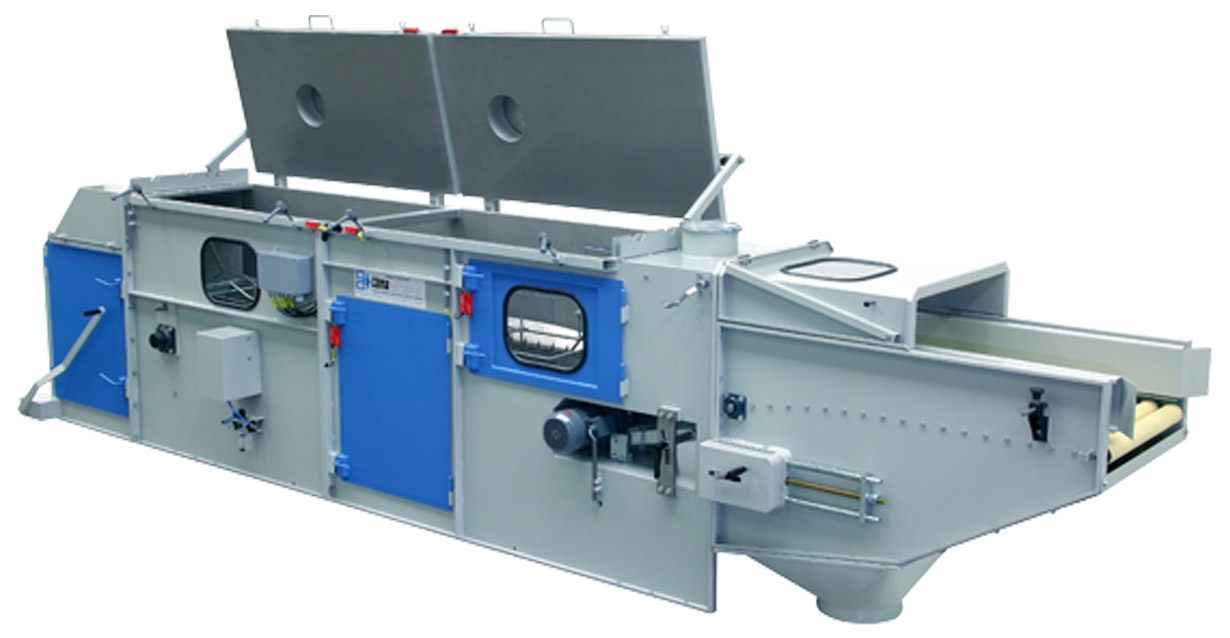

Automatic Bagslitting & Emptying unit

Manual emptying and handling of bags is very labour intensive and can generate an unacceptably high dust level. Many of the products handled can be dangerous if inhaled or if they come into contact with the skin. It creates a working environment with serious health dangers resulting in a lowering of operator efficiency and production capacity.

An effective bag emptying and discharge system can make the difference.

Optimal Solution for Bag Emptying Problems

The automatic bagslitter is suitable for the continuous and dustfree handling of all types of single- or multi-layered bags. Paper, plastic, large, small, dense- or light-filled with granular or powdered products, the "Galahad" will cut and empty them without problems. Depending on the execution, properties of the product and the condition of the bags, capacities can be reached up to 40 tons per hour. The standard execution will handle approximately 20 tons per hour.

With a large choice of ancillary equipment the "Galahad" can be enhanced to a complete discharge installation.

Bags to Bulk installation for plastic powders and granules incorporatingthe "Galahad" automatic bag emptying unit.

Efficient Bag Handling

The Galahad method of operation is simple but very effective. It ensures that the bags are emptied with minimal residue (0,01% - 0,1% for free flowing products).

By the appropriate design, the "Galahad" can be operated by one man only and offers you an economic solution for your bag emptying problems.

Complete Installation

- Dust filter unit

- Belt conveyor

- Rotating-brush cleaning unit

- Automatic baling press

- Bag compactor

- Tilting/Scissor lift table

- Rotary valve

- Screw conveyor

- Rotating sieve or built-in vibrating screen

- Crusher/Lump breaker